Introduction

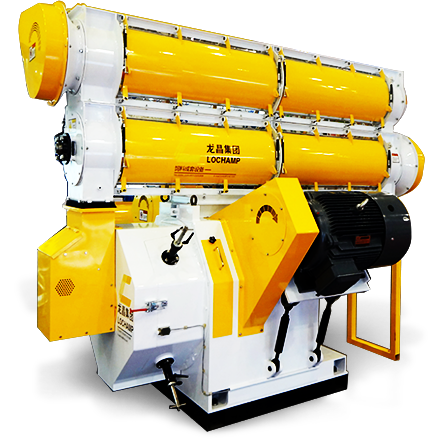

Feed pellet mill,also called feed pellet machine, pelleting machine, or pelletizer machine, is a

novel granulator produced by Lochamp patent technology. Feed pellet mill is equipped with high quality ring

die, press roller and advanced technology. The transmission system adopts dual-motor and V-belt drive with

small area, uniform force, simple structure, easy operation and maintenance. Feed pellet mill can also convert

motor and ring die, adapted to different production capacities and needs of different specification, to

achieve ideal technical and economic benefits.

Feed pellet mill is mainly composed of three parts--feeder, conditioner and pellet mill host, which

is consisted of body, chassis, hollow spindle assembly, ring die, roller assembly, cutter components, security

devices, the main motor drive system, etc.

Currently it has been formed pelletizing series including livestock and poultry feed, ruminant feed

and aquatic feed.

Introduction

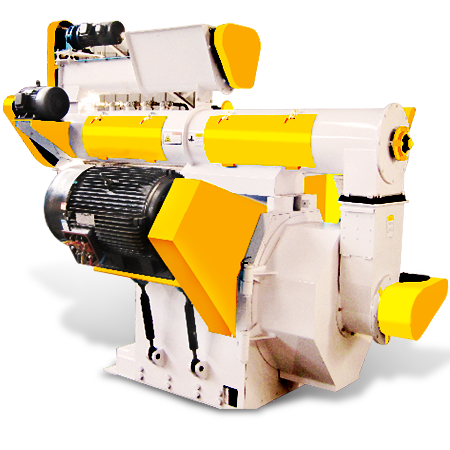

Biomass pellet machine,also called wood pellet machine,wood pellet mill.According to our experience

in industries of biomass, LoChamp have designed MZLH pellet machine. Biomass pellet mill can be used to

process various kinds of material like wood chips, straw, rice husk,sawdust, paddy straw, sun flower stalk,

hulls, forestry wastes, chemical waste and many other wastes or solid powder materials.

English

English 中文

中文 Español

Español العربية

العربية Pусский

Pусский Robot Palletiser

Robot Palletiser Biomassmill

Biomassmill

Fengshou Road, Zhouzhuang Industrial Park, Jiaozuo City, Henan Province,China .

Fengshou Road, Zhouzhuang Industrial Park, Jiaozuo City, Henan Province,China . 0086 - 0371 - 89910659

0086 - 0371 - 89910659

0086 - 0371 - 89910657

0086 - 0371 - 89910657 Lochamp-International

Lochamp-International